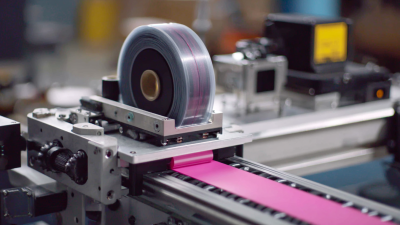

Pneumatic Friction Welding Baler - Quality Solutions from Top China Manufacturer

For your industrial needs, consider our Pneumatic Friction Welding Baler. As a manufacturer committed to quality, we provide robust equipment that enhances efficiency and durability. This baler is ideal for factories aiming to optimize production processes and reduce waste. Designed to accommodate various materials, our balers ensure adaptability to meet your specific requirements. Whether you seek wholesale options or a reliable partner for bulk purchases, Wenzhou Handpack Machinery Co., Ltd. is poised to fulfill your needs. With a dedication to customer satisfaction, we aim to deliver exceptional service and support throughout your purchasing journey. Join the ranks of businesses that have transformed their operations with our advanced machinery. Enhance your manufacturing capabilities with our Pneumatic Friction Welding Balers!

China’s Best-Selling Pneumatic Friction Welding Baler Custom Solutions, Application

In recent years, the demand for efficient and reliable packaging solutions has surged, particularly in the manufacturing and logistics sectors. Among these solutions, pneumatic friction welding balers have emerged as a top choice for packaging professionals looking to optimize their processes. These advanced machines provide robust performance, enabling businesses to effectively bundle a variety of products. By offering custom solutions tailored to specific needs, manufacturers can ensure seamless integration into existing workflows, ultimately enhancing productivity and reducing operational costs. The versatility of pneumatic friction welding balers is a significant advantage. They are designed to work with multiple types of packaging belts, including PET, PP, and Steel, making them suitable for diverse applications across different industries. Whether it's for securing goods in transit or creating compact packages for storage, these balers meet the stringent requirements of modern supply chains. Furthermore, their user-friendly design facilitates ease of operation, allowing workers to achieve high-quality results without extensive training. Investing in a pneumatic friction welding baler can transform the packaging process for companies around the globe. By leveraging advanced technologies and customization options, businesses can enhance their packaging efficiency, improve product protection, and stay competitive in an ever-evolving market. As the industry continues to grow, exploring innovative packaging solutions will be vital for success.

China’s Best-Selling Pneumatic Friction Welding Baler Custom Solutions, Application

| Feature | Specification | Application | Customization Options |

|---|---|---|---|

| Welding Speed | 50 mm/s | Automotive Parts | Speed Adjustment |

| Pressure Range | 0-200 bar | Construction Materials | Pressure Control System |

| Power Consumption | 5 kW | Aerospace Components | Energy Efficient Options |

| Cooling System | Water-Cooled | Electronics | Custom Cooling Solutions |

| Control System | PLC-Based | Heavy Industry | Programmable Logic Controllers |

Best Chinese Pneumatic Friction Welding Baler in 2025 Where Service Meets Innovation

D

Daniel Lee

The product’s quality is remarkable. The after-sales service was also efficient and highly respected.

08 July 2025

L

Linda Nelson

Wonderful product! The service team was prompt in addressing my questions and concerns.

26 June 2025

H

Hannah Collins

Lovely product! The after-sales service was friendly and professional.

06 July 2025

S

Samuel Foster

Great product quality! The customer service team was proactive and very helpful.

23 June 2025

I

Isaac Ross

The product is of premium quality! The after-sales team was always ready to assist.

24 June 2025

B

Bella Rogers

I highly recommend this seller! The product quality is impeccable and service is top-tier.

01 June 2025