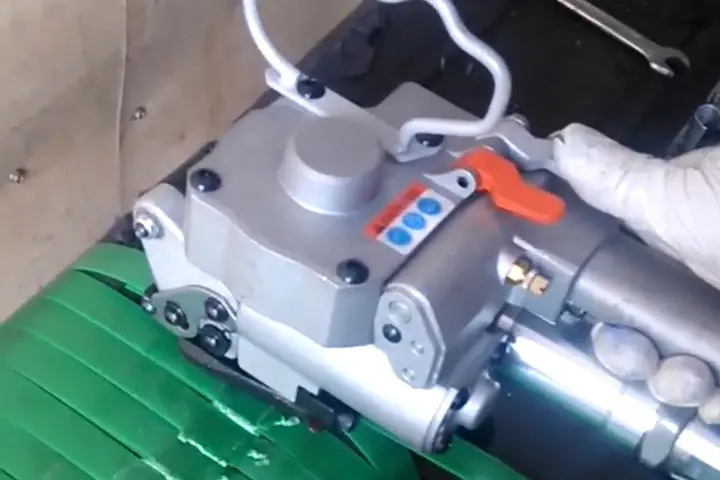

Pneumatic Cord Strap Tensioner XW50

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Product Overview

Pneumatic cord strap tensioner with cutter is a specialized industrial tool designed to automate two critical steps in cord strap packaging: tensioning (tightening the cord strap around packages, bundles, or pallets) and cutting (trimming excess strap after achieving optimal tension). Powered by compressed air (instead of electricity or batteries), it delivers consistent force for secure, uniform bundling—making it ideal for high-volume, heavy-duty applications like logistics, manufacturing, and construction. Unlike manual tensioners that rely on operator strength (and risk inconsistent tension), this tool ensures reliable load stability, preventing shifting or damage during transportation, storage, or handling.

Product Parameters

| Model | XW50 | |

| Applicable packing strap | Cord strap | |

| Air pressure | 0.4-0.8Mpa | |

| Packing strap size | strap width | 10-50mm |

| strap thickness | 0.6-2.0mm | |

| Tensioning force | ≥8000N/0.6Mpa | |

| Weight | 4.7kgs | |

| Size | 315*143*155mm | |

Product Features

Key Features

- High Tension Consistency: Pneumatic power delivers uniform force across every cycle, eliminating human error (e.g., uneven tension from manual tools) and ensuring all bundles meet the same security standards—critical for compliance in industries like pharmaceuticals or electronics.

- Fast Workflow: Combines tensioning and cutting into one step, reducing cycle time to 3–8 seconds per bundle (far faster than manual tools, which require separate tensioningand cutting).

- Durability for Heavy Use: Designed for industrial environments—resistant to dust, debris, and minor impacts. Pneumatic motors have fewer moving parts than electric motors, lowering maintenance needs (e.g., no batteries to charge or replace).

Typical Applications

This tool excels in high-volume or heavy-duty settings where speed, consistency, and reliability are non-negotiable:

- Logistics & Warehousing: Tensioning and cutting cord straps around palleted goods (e.g., appliances, cartons, or bulk packages) to secure loads for forklift handling or truck shipping.

- Construction: Bundling lumber, PVC pipes, rebar, or drywall sheets—where ruggedness and fast cycle times keep on-site packaging efficient.

- Manufacturing: Securing finished products (e.g., furniture, machinery parts) or raw materials (e.g., plastic pellets, metal coils) for in-plant transport or outbound delivery.

- Agriculture: Bundling hay bales, irrigation tubes, or farm equipment parts—with weather-resistant cord straps and durable tool construction standing up to outdoor use.