Manual Strapping Tensioner SKL-32/19

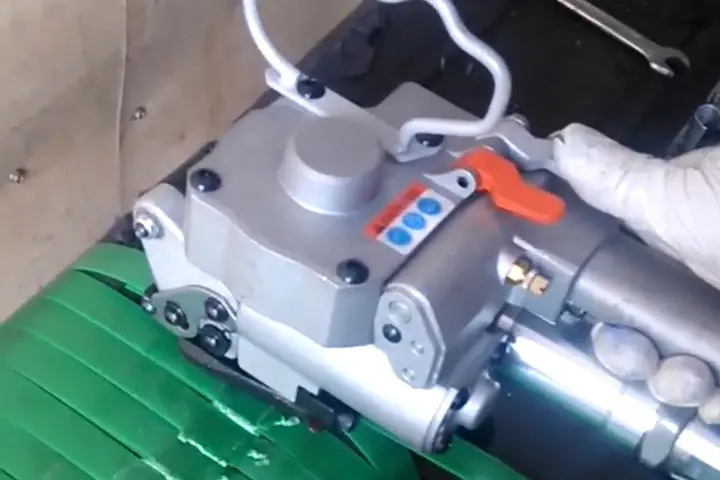

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

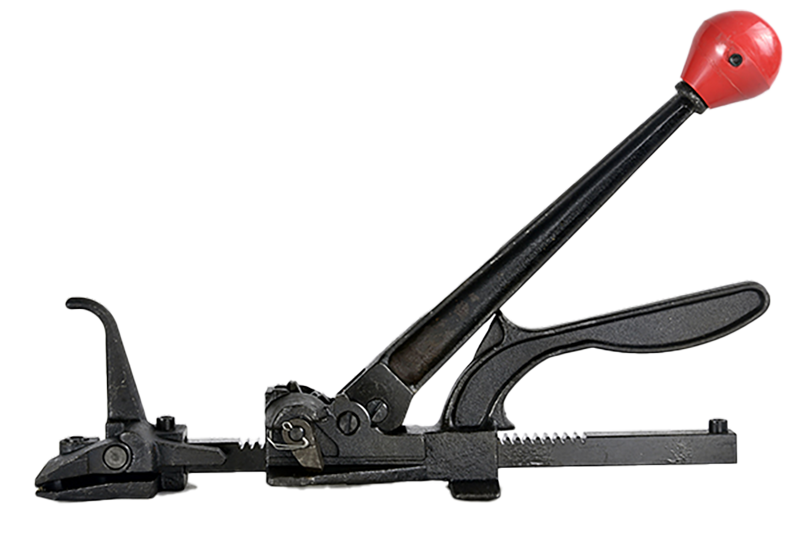

Product Features

Primary Function: The tool is designed to tighten steel strapping securely around a load before the strap is sealed with a metal lock (seal). Its integrated design also allows for the severing of the strap after the sealing process is complete.

Strap Compatibility: It is typically compatible with a range of steel strap dimensions. The model number "32/19" suggests it is suited for straps approximately 32 mm in width and 0.8-1.2 mm in thickness, a common specification in this series. It may also handle other width like 19mm and 25mm

Tensioning Force: Capable of generating a high tensioning force (pull force), typically greater than 6.7 KN, ensuring tight and secure bundling of heavy loads

Robust Construction: Built for durability and industrial use, often constructed from forged steel alloys to withstand the high forces involved during operation. The approximate weight of similar tools is around 3.2kgs.

Operation: The tool uses a manual lever-action mechanism. The process involves placing the strap end on a friction plate, positioning the strap under a feed wheel, and then swinging the tensioning handle repeatedly to achieve the desired tightness

Integrated Cutting Function: After the strap is sealed using a separate crimping tool (e.g., an SKS-type seal clamp), the fixed handle of the tensioner is raised to a 90-degree angle against the sealed point and swung to shear and cut the steel strap cleanly

Safety and Ergonomics: Designed with handles that provide leverage and may include features for operator comfort and control during the tensioning and cutting process.

Product Parameters

| Manual Strapping Tensioner SKL-32/19 | |

| Tape material: | steel strap |

| Tape size: | (19-32)×(0.8-1.2)mm |

| Tool Weight: | 3.2kg |