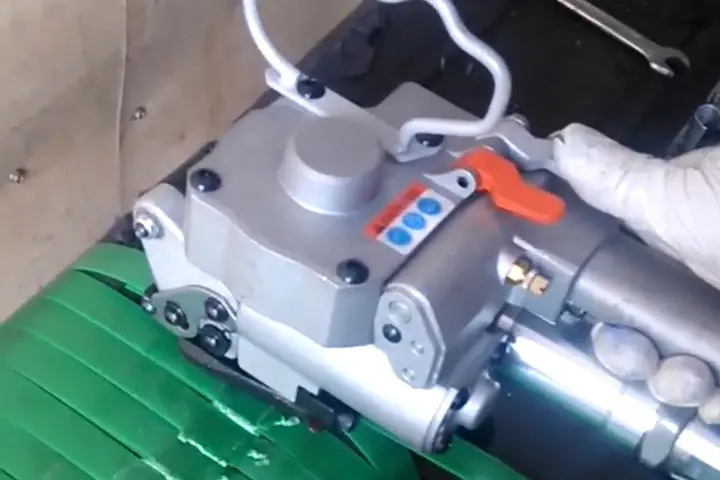

Manual Steel Strapping Tensioner SGL-19

01

Operate

convenient operation,smart and light, big power design

02

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

03

Performance

high automatic working performance, high controllability of tension and welding

04

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

05

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

06

Patent

patent design and avoid fatigue

Product Overview

Manual steel strapping tensioner is a practical, hand-operated tool specifically engineered to tighten steel strapping around packages, bundles, or heavy loads, effectively creating a firm, secure hold before the strapping is sealed. Unlike automated pneumatic or hydraulic tensioners that depend on external power sources, this tool relies entirely on human force to generate the necessary tension. This manual design gives it distinct advantages: it is highly portable, easy to carry and use across different work areas; it is cost-effective, as it avoids the high purchase and maintenance costs of power-driven alternatives; and it is exceptionally suitable for low-volume strapping tasks or locations without access to electricity, compressed air, or hydraulic systems—such as remote construction sites, small warehouses, or temporary packaging stations.

As a critical component in strapping systems, the manual steel strapping tensioner does not work alone. It operates in conjunction with a separate sealer (or a combined tensioner-sealer tool for more efficiency) to fully complete the strapping process, ensuring loads stay stable during storage or transportation. Overall, this tool is versatile and reliable, excelling at applying controlled tension to steel strapping in low-volume or off-grid scenarios. Its simplicity of operation, strong portability, and economic value make it an essential asset in packaging and material handling operations where both strapping precision and load security are top priorities.

Product Parameters

| Model | Manual steel strapping tensioner SGL-19 |

| Applicable packing strap | steel strap |

| strap width | 13-19mm |

| strap thickness | 0.5-0.8mm |

| Weight | 2.878kg |

Product Features

Key Features and Advantages

- Portability: Lightweight (usually 2–4 kg) and compact, with no cords or hoses, making it easy to carry and use in tight spaces, remote locations, or on job sites.

- Cost-Effective: Lower upfront and maintenance costs compared to powered tensioners, as it has fewer moving parts and requires no external power sources.

- Controlled Tension: Manual operation allows operators to feel and adjust tension based on the load’s fragility or the strap’s strength, reducing the risk of over-tightening.

- Durability: Constructed from high-strength steel or alloy, the tool withstands heavy use, impacts, and exposure to harsh environments (e.g., construction sites, outdoor storage yards).

- Compatibility: Works with standard steel strapping (widths typically 13mm to 19mm) and pairs with various sealers, including crimping tools for metal buckles or strapless sealers for buckle-free joints.

Typical Applications

- Warehousing and Logistics: Securing palletized goods, metal coils, or heavy boxes for shipping.

- Construction: Tightening straps around lumber, pipes, or concrete blocks to prevent shifting during transport.

- Manufacturing: Bundling raw materials (e.g., steel bars, aluminum sheets) or finished products for storage.

- Field Operations: Strapping equipment or supplies in remote areas (e.g., mining sites, agricultural facilities) where power is unavailable.

The use of pneumatic strapping machines

The use of pneumatic strapping machines

Pneumatic strapping tools 13-19mm (1/2 inch to 3/4 inch) is widely used in various industries and warehouses. Pneumatic strapping tool is one of the easiest and safest ways to band pallets. It is easy to use and quick to adjust. The device is excellent in balance and can be used for vertical and horizontal strapping. Handheld strapping machines can be used for plastic PET and PP strapping tapes.

With a manual pneumatic machine, and the sealing, tensioning, and cutting are completed at one time.

01/01

01