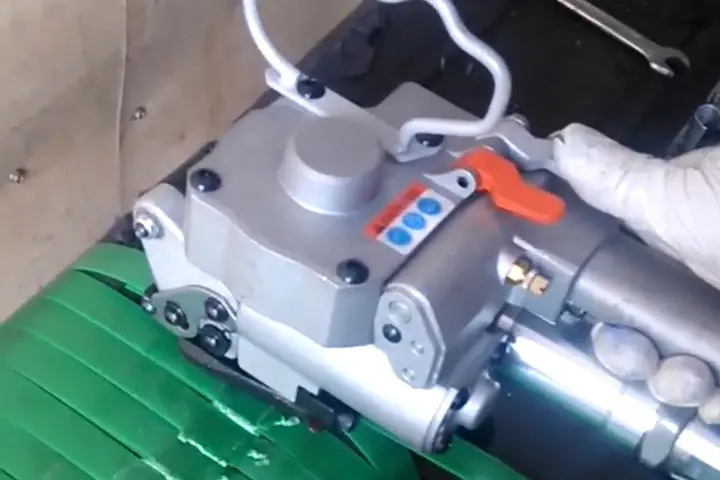

Manual Fiber Cord/Woven Webbing tensioner SD190

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Product Overview

The Manual Fiber Rope/Braid Tensioner is an innovative handheld tool designed for effectively tightening fiber ropes and braids across a wide range of loads. It’s ideal for applications such as strapping, palletizing, and securing cargo during transport. Unlike traditional, heavy, and bulky steel strapping tools, this tensioner is lightweight and easy to use, making it suitable for operators of all skill levels. It’s optimized for non-metallic strapping materials, ensuring safe and secure securing without damaging the load. This versatility makes it an essential tool for the logistics and shipping industries.

Product Parameters

| Model name | tensioner | SD190 |

| Applicable packing strap | Fiber Cord/Woven Webbing | |

| Packing strap size | strap width | 13-19mm |

| Size | 270*140*68mm | |

| Net weight | 1.4KGS | |

Product Features

1.Manual Operation

• Uses hand leverage(ratcheting mechanism) to apply tension without power tools.

• Ideal for environments where electricity or batteries are impractical.

2.Compatibility

• Works with fiber straps of common widths (13–19 mm).

• Avoids strap damage with gentle gripping surfaces.

3.Tensioning Mechanism

• Ratchet System: Incrementally tightens the strap with each lever pull.

• Grip Teeth: Secures the strap during tensioning to prevent slippage.

• Release Lever: Quickly loosens the tool after strapping.

4.Applications

• Securing lightweight to medium loads (boxes, cartons, pipes, timber).

• Common in logistics, agriculture, and small-scale packaging.

5.Advantages

• Portable, low-cost, and requires no external power.

• Safer for delicate loads compared to steel strapping tools.

Typical Components:

• Tensioning Handle: Ratcheting lever for incremental tightening.

• Strap Clamp/Grip Jaw: Holds the strap in place during tensioning.

• Strap Slot: Guides the strap through the tool.

• Cutting Edge(optional): Some models include a blade to trim excess strap.

Usage Example:

1.Loop the fiber strap around the load.

2.2. Insert the strap end into the tool’s slot and engage the grip teeth.

3.3. Pull the lever repeatedly to tighten.

4.4. Seal the strap with a buckle or friction weld(using a separate sealer).