Manual Buckle-Free Steel Strapping Tool SG192

01

Operate

convenient operation,smart and light, big power design

02

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

03

Performance

high automatic working performance, high controllability of tension and welding

04

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

05

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

06

Patent

patent design and avoid fatigue

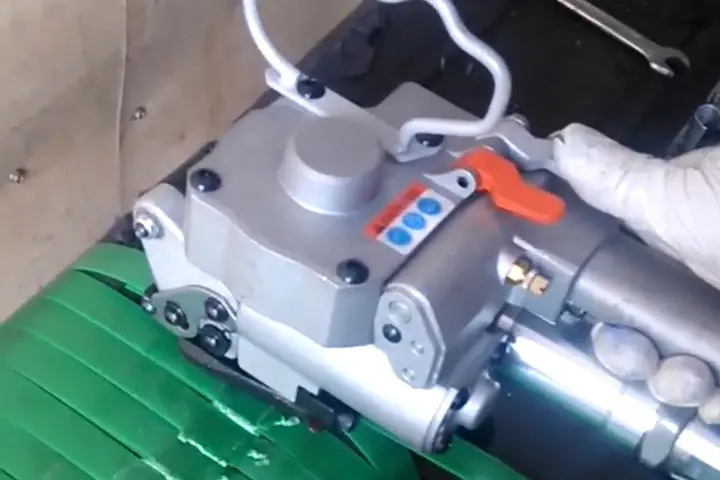

Product Overview

The SG192 Manual Buckle-Free Steel Strapping Tool is a sturdy, high-efficiency hand-operated tool built for secure load bundling—no extra buckles or seals required. It merges portability with top-tier performance, which makes it a perfect fit for a range of industrial packaging scenarios where dependability and cost-saving are of the utmost importance.

A manual sealless steel strapping tool is a hand-powered device crafted to secure heavy loads with steel strapping, eliminating the need for metal buckles, clips, or outside fasteners. Different from automated or pneumatic tools, it depends fully on manual force to tighten the strap and form a strong, long-lasting connection via mechanical deformation. This process works by "cold-welding" the overlapping ends of the steel strap. This type of tool is highly regarded for its portability, straightforward design, and reliability, especially in low-volume operations or remote locations where there’s no access to power sources.

Product Parameters

| Model | manual buckle free steel strapping tool SG192 |

| Applicable packing strap | steel strap |

| strap width | 13-19mm |

| strap thickness | 0.38-0.8mm |

| Lock mode | yin and yang buckle |

| Joint force the max. 70%-80% | the max. 70%-80% |

| Weight | 3.5kgs |

| size | 390*330*95mm |

Product Features

Key Features and Advantages

- No Fasteners Required: Eliminates the need for metal buckles, clips, or seals, reducing material costs and simplifying inventory management. The integrated joint is as strong as the strap itself, often achieving 70–80% of the steel’s tensile strength.

- Portability: Lightweight (typically 3–5 kg) and compact, the tool requires no electricity, air compressors, or hoses, making it ideal for fieldwork, remote job sites, or areas with limited infrastructure.

- Durability: Constructed from high-strength alloy steel, the tool withstands heavy use and harsh environments (e.g., construction sites, outdoor storage yards) without compromising performance.

- Simplicity: Minimal moving parts and intuitive lever operation make it easy to use with basic training, reducing reliance on skilled operators.

- Versatility: Compatible with standard steel strapping (widths from 13mm to 25mm) and adaptable to various load types, from metal pipes to lumber bundles.

Typical Applications

- Construction Sites: Securing lumber, steel bars, or concrete blocks for on-site storage or transport.

- Small Warehouses: Bundling heavy items for shipping where automated systems are unnecessary.

- Field Operations: Strapping equipment or materials in remote locations (e.g., mining sites, agricultural facilities) without power access.

- Repair and Maintenance: Temporarily securing machinery or components during repairs or transit.

The use of pneumatic strapping machines

The use of pneumatic strapping machines

Pneumatic strapping tools 13-19mm (1/2 inch to 3/4 inch) is widely used in various industries and warehouses. Pneumatic strapping tool is one of the easiest and safest ways to band pallets. It is easy to use and quick to adjust. The device is excellent in balance and can be used for vertical and horizontal strapping. Handheld strapping machines can be used for plastic PET and PP strapping tapes.

With a manual pneumatic machine, and the sealing, tensioning, and cutting are completed at one time.

01/01

01