Manual Buckle Free Steel Strapping Tool A333

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Product Overview

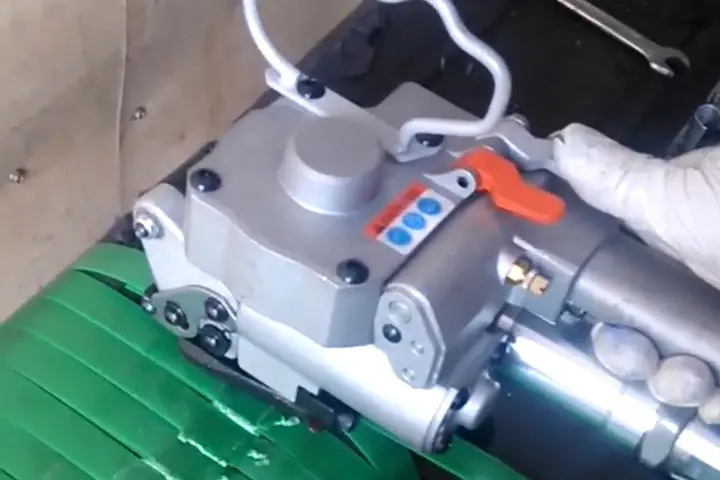

The Manual Steel Strapping Buckle-Free Tool Model A333 is a portable, efficient, and cost-effective packaging device specifically engineered for tensioning, sealing, and cutting steel strapping in various industrial and logistics scenarios. Designed to eliminate the need for traditional metal buckles during the strapping process, it streamlines packaging workflows while ensuring secure and reliable load fixation.

Product Parameters

| Model name | Manual Buckle-free Steel Strapping Tool A333 | |

| Description | it can operate manually,which connect with function of tensioning,sealing and cutting.It is widely used in manufacturing,metallurgy,transportation ect,. Steel bands of common and high tensile strength are both acceptable. | |

| Feature | 1. convenient operation,smart design, no need to connect any power | |

| 2. buckle free,with double pressure instructure to achieve the connection of two strap, reliable performance of connection | ||

| 3.high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages | ||

| 4.all the parts with High - strength aluminum alloy to keep long time use, | ||

| reliable design and advanced manufacturing technology | ||

| 5.patent design and avoid fatigue | ||

| Applicable packing strap | steel strap | |

| Packing strap size | strap width | 13-19mm |

| strap thickness | 0.38-0.8mm | |

| Lock mode | yin and yang buckle | |

| Joint force | the max. 70%-80% | |

| Weight | 3.9kgs | |

| size | 387*168*308mm |

Core Functions & Operational Logic

This tool integrates three key functions—strapping tensioning, buckle-free sealing, and strapping cutting—into a single handheld unit, enabling one-person operation with simple steps:

1.Tensioning: Insert the free end of the steel strapping (typically 12-16mm in width, compatible with most standard industrial steel straps) into the tool’s tensioning mechanism. Rotate the tool’s tensioning handle clockwise; the internal gear system will gradually tighten the strapping around the load, allowing users to adjust tension based on load weight (up to a maximum tension of ~500N, suitable for medium-weight packages like cartons, wooden crates, or metal parts).

2. Buckle-Free Sealing: Once the desired tension is achieved, flip the tool’s sealing lever. The device uses a mechanical crimping principle to press and interlock the overlapping sections of the steel strapping (no buckles required). This creates a tight, tamper-resistant seal that avoids the cost and waste of disposable buckles, while also enhancing seal durability (the crimped joint can withstand up to 80% of the strapping’s original tensile strength).

3. Cutting: After sealing, press the built-in cutting blade (made of high-hardness alloy steel for wear resistance) to trim the excess strapping cleanly. The blade’s safety design prevents accidental cuts during operation.

Key Features & Advantages

Buckle-Free Design: Reduces packaging costs by eliminating the need to purchase and store metal buckles; also minimizes waste, aligning with eco-friendly packaging trends.

Portability & Ergonomics: Weighing approximately 3.2kg and featuring an ergonomic rubberized handle, it is easy to carry and operate for extended periods—ideal for on-site packaging in warehouses, factories, or construction sites where power access is limited.

Durable Construction: The tool body is crafted from high-strength aluminum alloy, and critical components (like the tensioning gears and cutting blade) are treated with heat for enhanced hardness. This ensures resistance to impact, corrosion, and daily wear, extending the tool’s service life to 3-5 years under regular use.

Wide Compatibility: Works with galvanized steel strapping and black annealed steel strapping (thickness: 0.3-0.6mm), making it suitable for packaging applications in industries such as electronics, machinery, building materials, and logistics.

Typical Application Scenarios

Securing wooden crates or pallets loaded with industrial parts (e.g., auto components, mechanical gears).

Bundling heavy cartons or cardboard boxes for long-distance shipping (prevents package deformation during transit).

Packaging metal pipes, profiles, or sheet metal to avoid scratches or displacement during storage or transportation.

On-site packaging in remote locations (e.g., construction sites, outdoor storage yards) where electric or pneumatic strapping tools cannot be used due to power constraints.

Maintenance Tips

To ensure consistent performance, regular maintenance is recommended:

After each use, wipe the tool body and tensioning mechanism with a dry cloth to remove dust or strapping residue.

Lubricate the tensioning gears and pivot points monthly with industrial lubricating oil (avoid using excessive oil to prevent contamination of strapping).

Replace the cutting blade every 6-12 months (depending on usage frequency) to ensure clean, smooth cuts; use only original replacement blades to maintain compatibility.

Store the tool in a dry, cool environment to prevent rusting of metal components.