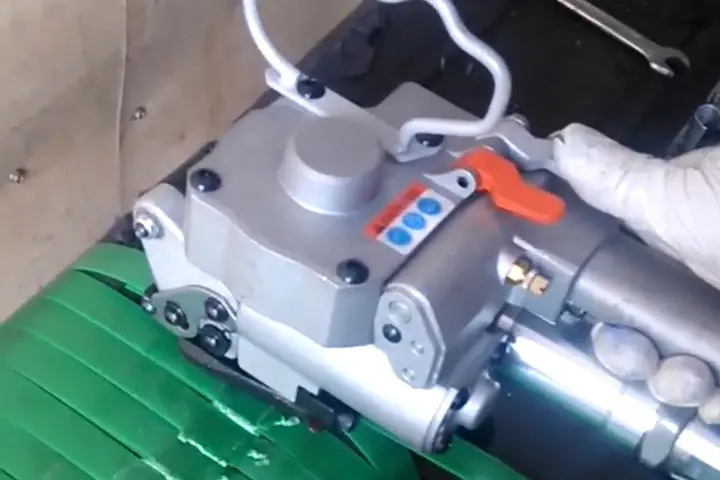

Manual 3-in-1 PP Strapping Tool SD3IN1

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Product Parameters

| Description name | Manual PP strapping tool | |

| Usage | widely used in paper industry,aluminum alloy, steel, wood, wooden box package,chemical fiber,cotton spinning,tobacco,chemical,metal products,etc.. | |

| Feature | 1. convenient operation,smart design, easy remove | |

| 2.High speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages | ||

| 3.all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology | ||

| 4.patent design and avoid fatigue | ||

| Manual 3-in-1 PP Strapping Tool Model SD3IN1 | ||

| Model | SD3IN1 | |

| Applicable packing strap | PP | |

| Packing strap size | strap width | 13mm / 16mm |

| strap thickness | 0.4-0.9mm | |

| Net weight | 2.7kgs | |

| Size | 377*150*150mm | |

Core Functions & Step-by-Step Operation

Tailored to PP strapping’s flexibility and tensile characteristics, the SD3IN1 operates with intuitive mechanical controls, requiring no electricity or compressed air. Here’s its standard workflow:

Strapping Tensioning: First, loop the PP strapping (compatible with 5-15mm width, 0.5-1.2mm thickness—common for bundling cartons, packages, or small pallets) around the load. Insert one end of the strapping into the tool’s tensioning slot, then rotate the ergonomic tensioning knob clockwise. The tool’s internal roller and clutch system gradually tightens the strapping around the load, with adjustable tension (up to ~300N) to avoid over-tightening (which can damage PP strapping or delicate loads like cardboard boxes).

Mechanical Sealing: Once the desired tension is achieved, lock the tension using the tool’s built-in ratchet mechanism. Next, place a PP strapping seal (typically a metal or plastic buckle, compatible with the tool’s seal slot) over the overlapping ends of the strapping. Flip the tool’s sealing lever downward—this activates a crimping jaw that presses the seal tightly around the strapping, creating a secure, tamper-proof joint. The seal design ensures the joint retains up to 70-80% of the PP strapping’s original tensile strength, sufficient for most shipping and storage needs.

Clean Cutting: After sealing, release the tension lock and press the tool’s integrated cutting blade (made of high-carbon steel for sharpness and durability). The blade trims the excess strapping cleanly at the seal, leaving no jagged edges. A safety guard covers the blade when not in use, reducing the risk of accidental cuts.

Key Features & Competitive Advantages

All-in-One Convenience: Combines tensioner, sealer, and cutter in one tool, reducing tool storage space, carrying weight, and operational time. Unlike separate tools, it eliminates the need to switch between devices mid-task.

PP-Specific Optimization: Engineered to handle PP strapping’s unique properties (e.g., flexibility, lower rigidity compared to steel strapping). The tensioning system avoids stretching or breaking PP, while the sealing jaw is sized to fit standard PP seals for consistent results.

Ergonomic & Portable Design: Weighing only 2.1kg (lighter than many steel strapping tools), it minimizes user fatigue during extended use. The handle features a non-slip rubber grip, and the tool’s compact size (approx. 30x15x8cm) makes it easy to carry or store in small workshops or delivery vans.

Cost-Effective: No power source required (saving energy costs) and compatible with affordable PP strapping and standard seals. The tool’s durable construction (aluminum alloy body, reinforced plastic components) reduces maintenance and replacement expenses.

Wide Compatibility: Works with both regular and recycled PP strapping, as well as common seal types (metal buckles, plastic snap seals), making it adaptable to diverse packaging needs (e.g., bundling books, electronics, food parcels, or small industrial parts).

Typical Application Scenarios

The SD3IN1 is ideal for light to medium-duty packaging tasks where portability and simplicity are prioritized:

Bundling individual cartons or small packages for shipping (e.g., e-commerce fulfillment centers, retail stores).

Securing small pallets of goods (e.g., beverage cases, household appliances) for warehouse storage or local delivery.

Packaging fragile items (e.g., glassware, electronics in cardboard) thanks to adjustable low-tension settings that prevent load damage.

On-the-go packaging (e.g., delivery trucks, remote storage sites) where access to electricity or pneumatic tools is limited.

Maintenance & Care Tips

To prolong the SD3IN1’s lifespan and ensure consistent performance:

Clean Regularly: After each use, wipe the tensioning rollers, sealing jaw, and cutting blade with a dry cloth to remove PP strapping residue (which can build up and

affect tension). For stubborn residue, use a mild solvent (e.g., isopropyl alcohol) and avoid abrasive cleaners.

Lubricate Key Parts: Every 4-6 weeks (or after 500+ uses), apply a small amount of light machine oil to the tensioning knob’s pivot points and the sealing lever’s

hinges. Do not over-lubricate, as excess oil can stain PP strapping.

Blade Replacement: Replace the cutting blade when it starts to leave ragged cuts (typically every 8-12 months for regular use). Use only manufacturer-approved

eplacement blades to ensure compatibility with the tool’s cutting mechanism.

Storage: Keep the tool in a dry, cool area to prevent rust on metal components (e.g., the sealing jaw) and degradation of plastic parts. Avoid dropping the tool or

exposing it to extreme temperatures (which can warp PP-compatible components).