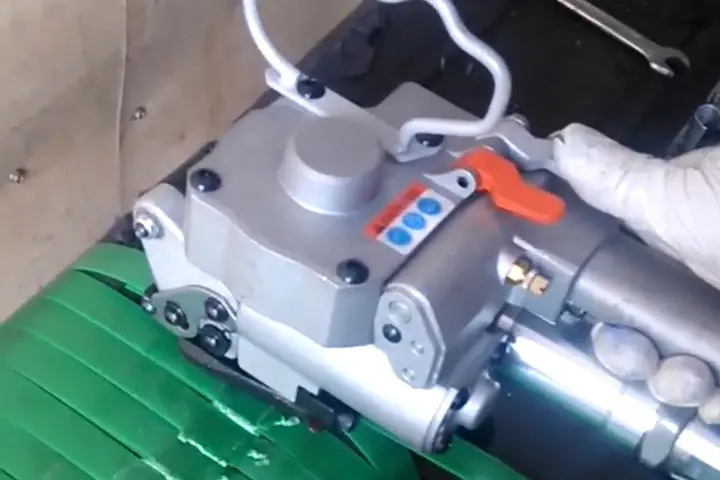

Long Handle Cutting Tool GJ32

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Key Features & Specifications

| Long Handle Cutting Tool GJ32 | |

| Tape material: | steel strap |

| width: | 13-50mm |

| thickness: | 0.35-2.5mm |

| Tool Weight: | 2.8kg |

| Tool size: | 620*255*60mm |

Key Features & Specifications

Primary Function: Designed exclusively for cutting through steel strapping. Its geometry and leverage are optimized for this single task, providing a clean cut without fraying the strap excessively, which minimizes the risk of sharp, dangerous edges (snagging).

Robust Construction: Built for extreme durability and high force application. Typically constructed from forged alloy steel or high-carbon steel, making the tool incredibly strong and resistant to deformation or breaking under stress.

Leverage Design: Features long, heavy-duty handles that provide significant mechanical advantage. This allows an operator to easily cut through thick, hardened steel straps with minimal physical effort. The handles are often coated with a non-slip, comfort grip to ensure control and reduce hand fatigue during repeated use.

Cutting Head & Blades: Equipped with specially hardened, replaceable shear blades. The blades are designed to meet precisely, creating a clean shearing action rather than a crushing one. The jaws are often angled to allow for easy placement under tight straps.

Safety Lock: Includes a safety latch or lock to secure the blades in a closed position when not in use. This is a critical safety feature for storage and transportation, protecting users from the sharp blades.

Typical Capacity: Capable of cutting steel strapping up to a specific width and thickness (e.g., up to 32mm / 1.25 inches wide and 1.0mm / 0.04 inches thick).