Wholesale Horizontal Pallet Strapping Machine | Premier Factory Suppliers

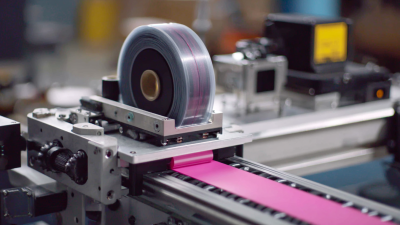

As a business owner, I understand the importance of efficiency and reliability in packaging processes. The Horizontal Pallet Strapping Machine is designed for those who prioritize quality and consistency in their operations. Ideal for manufacturers and wholesalers, this machine streamlines your packaging workflow with its durable construction, accommodating various pallet sizes and strap materials to ensure your products are secure for shipment. Manufactured by Wenzhou Handpack Machinery Co., Ltd., a recognized leader in the industry, our machines are built to last, minimizing downtime and maintenance costs. Choosing our equipment means investing in a dependable partner for your business. Together, let's enhance your packaging efficiency and meet your production demands effectively!

Key Steps to Choosing Horizontal Pallet Strapping Machine Custom Solutions, Factory-Direct Excellence

When selecting a horizontal pallet strapping machine, understanding the essential steps can significantly impact your packaging efficiency and productivity. First, consider the type of materials you'll be using; choose a machine that can handle various strapping options, such as PET, PP, and steel belts, to ensure versatility in your operations. This flexibility allows you to adapt to different packaging requirements and optimize costs based on the materials best suited for your products. Second, assess the machine’s automation capabilities and technical features. Modern machines offer advanced options like automatic tensioning and sealing, which can streamline the strapping process. Look for customizable features that align with your production needs, ensuring the solution you choose enhances workflow efficiency while reducing manual labor costs. Finally, consider factory-direct solutions that often provide significant quality assurance and lower purchase costs. Working directly with manufacturers can give you insights into their production processes and innovative technologies, ensuring you invest in a machine that meets high standards of excellence. Establishing a strong partnership with the right supplier can also facilitate future upgrades and support, helping you stay competitive in a rapidly evolving marketplace.

Key Steps to Choosing Horizontal Pallet Strapping Machine Custom Solutions, Factory-Direct Excellence

| Feature | Description | Importance | Custom Options |

|---|---|---|---|

| Machine Speed | The number of pallets strapped per hour. | High | Variable speeds available based on production needs. |

| Strapping Material Types | Types of strapping materials compatible with the machine. | Medium | PP, PET, and custom materials upon request. |

| Control System | Type of control interface: manual or automatic. | High | Touchscreen control options are available. |

| Safety Features | Safety mechanisms to protect operators. | High | Custom safety guards and emergency stop buttons. |

| Size Adjustability | The ability to adjust for different pallet sizes. | Medium | Manual or automatic adjustment options. |

| Maintenance Requirements | Frequency and ease of maintenance tasks. | Medium | Custom maintenance plans available. |

Trending Horizontal Pallet Strapping Machine Exceeds Industry Benchmarks Manufacturer

B

Brian Hill

Quality product that delivers on promises. The support team was knowledgeable and proactive.

03 June 2025

M

Matthew King

I’m very pleased with both the product and the service. They really care about their customers!

20 May 2025

R

Rachel Hill

The product quality truly stands out! Customer support was just as impressive, very professional.

26 May 2025

D

Daniel Robinson

Excellent product quality complemented by outstanding after-sales support!

16 May 2025

M

Matthew Green

The product quality is second to none! Their service team was especially helpful and friendly.

06 June 2025

B

Bella Rogers

I highly recommend this seller! The product quality is impeccable and service is top-tier.

01 June 2025