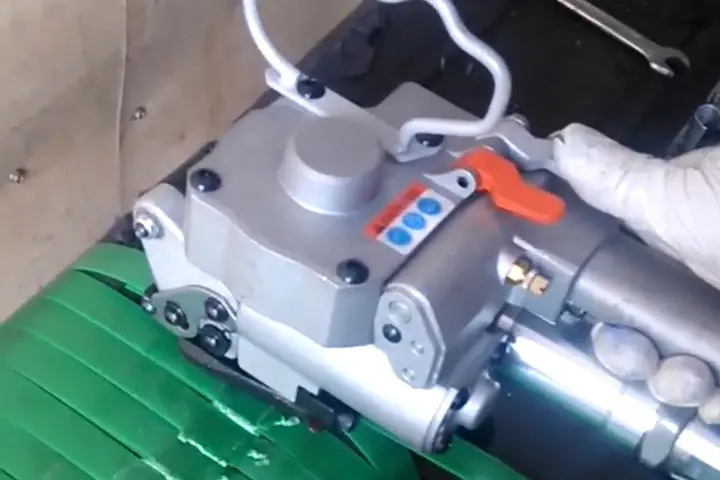

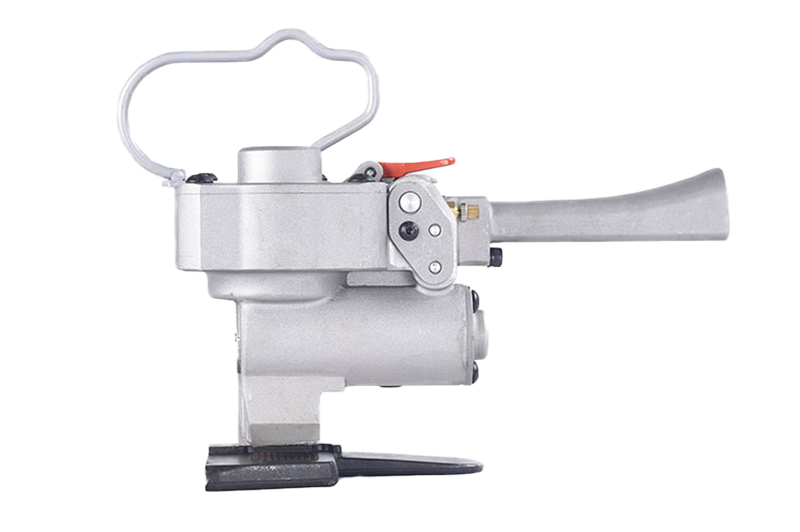

Hand-held Pneumatic splicing strapping tool RJ250

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Product Overview

The RJ250 is a handheld pneumatic welding machine designed for efficient and secure strapping through heat-sealing technology, specifically using friction-based thermal fusion to join materials without additional buckles or seals. It operates on compressed air (0.5–0.8 MPa), making it suitable for industrial environments where electricity is impractical or unsafe. Weighing only 2.5 kg, it combines portability with robust performance, featuring a compact design ( 150*82*175mm) for easy handling in tight spaces. Its primary advantage lies in its buckle-free operation, which reduces consumable costs and simplifies the sealing process while delivering consistent results for heavy-duty bundling tasks.

A Pneumatic Strapping Welding Machine is an industrial device designed to securely join strapping bands (typically made of PP, PET) using compressed air-driven heat and pressure. It is widely used in logistics, warehousing, and manufacturing for bundling heavy loads, securing pallets, and reinforcing packaging.

Product Parameters

| Description name | Hand-held Pneumatic splicing strapping tool RJ250 | |

| Packing Strap Size | strap width | 13-25mm |

| strap thickness | 0.5-1.2mm | |

| Welding adjusted time | 0.5-5s | |

| Applicable packing Strap | PP & PET | |

| Net Weight | 2.5KGS | |

| Size | 150*82*175mm | |

Product Features

Pneumatic Operation : Powered by compressed air (usually 0.5–0.8 MPa), ensuring fast, energy-efficient, and low-maintenance performance.

High-Strength Welds : Combines heat and pressure to fuse strapping ends, creating durable, tamper-proof seals.

Portable & Robust : Compact design for on-site use in warehouses or shipping docks; often features a lightweight aluminum or steel frame.

Quick Cycle Time : Completes welds in seconds, ideal for high-volume packaging lines.

Typical Applications:

Securing heavy cargo on pallets (e.g., bricks, machinery).

Reinforcing boxes and crates for transport.

Steel strapping in construction or metalworking industries.

Automated packaging systems in factories.

Advantages Over Manual/Other Tools:

✔ Consistent weld quality with minimal operator skill required.

✔ No batteries or heavy hydraulics—reliable in dusty/humid environments.

✔ Lower operational costs compared to electric or hydraulic welders.