Product Overview

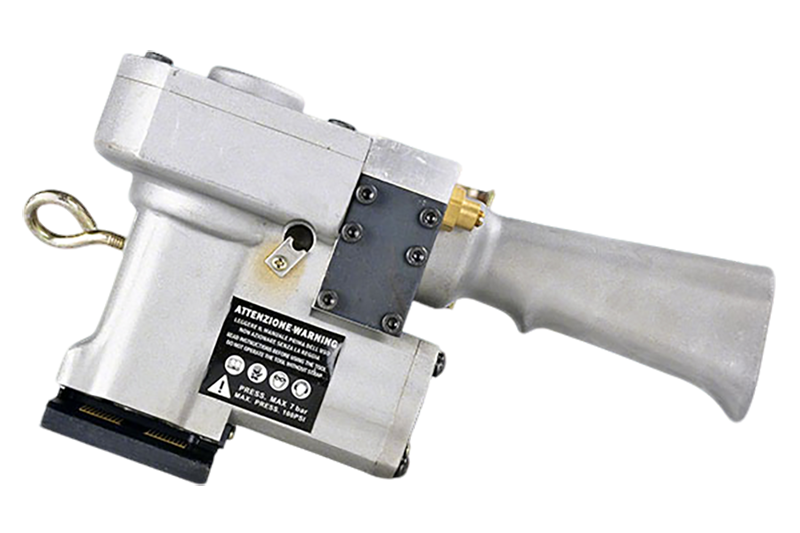

The RJ193 is a handheld pneumatic welder designed to achieve efficient and reliable bundling through heat sealing technology. Specifically, it uses a friction-based heat fusion process to complete the splicing of materials without the need for additional fasteners or seals.

Powered by compressed air, the device operates within a pressure range of 0.5–0.8 MPa, making it particularly suitable for industrial applications where power access is difficult or where electrical safety risks exist. The RJ193 excels in balancing portability and performance: weighing only 2.5 kg, it offers robust operation capabilities. Its compact design (240 × 108 × 135 mm) makes it easy to operate in confined spaces.

The core advantage of this welding machine is its “fastener-free operation” mode: it not only reduces consumables costs but also simplifies the strapping process while providing stable and consistent results for heavy-duty strapping tasks.

Product Parameters

| Description name |

Hand-held Pneumatic splicing strapping tool RJ193 |

| Packing Strap Size |

strap width |

13-19mm |

| strap thickness |

0.5-1.5mm |

| Welding adjusted time |

≤ 2s |

| Applicable packing Strap |

PP & PET |

| Net Weight |

2.5KGS |

| Size |

240*135*108mm |

Product Features

Power Source: Compressed air (operating pressure: 0.5–0.8 MPa; optimal pressure: 0.65 MPa)

Strapping Compatibility: Designed for polyester (PET) strapping with a width of 13–19 mm and thickness of 0.5–1.5 mm

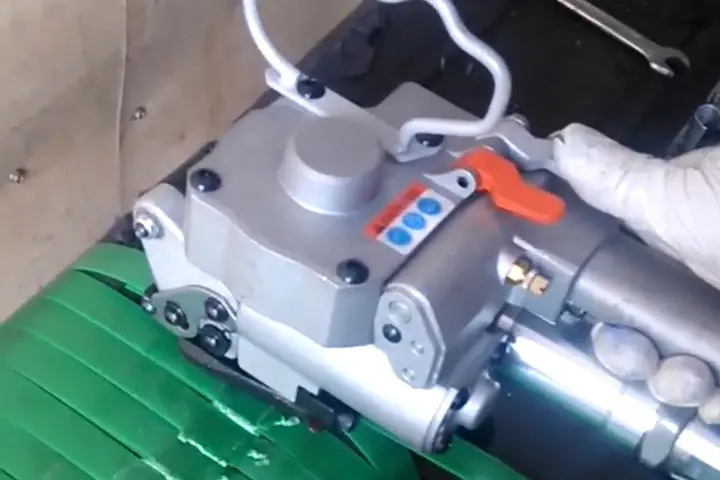

Sealing Method: Friction heat sealing (thermal fusion) that creates secure, buckle-free joints

Design: Lightweight (2.5 kg) and ergonomic, reducing operator fatigue during extended use

Durability: Constructed with high-strength alloy materials for longevity in demanding environments

Safety: Complies with vibration standards (ISO5349) and features a simple, intuitive operation.

Applications

The RJ193's outstanding performance makes it an ideal choice for the textile and packaging industries. In the textile sector, it delivers precise performance in everything from the centralized handling of cotton after harvest to the production and processing of various fibers and synthetic materials (such as polyester and nylon). For example, when baling cotton, it securely holds fluffy cotton balls together to prevent them from dispersing during transport. When packaging finished textile products, it tightly binds fabric rolls and clothing bales, ensuring product integrity and preventing wear and tear during transport.

RJ193 also offers significant advantages in logistics and warehousing scenarios. It eliminates the need for metal clips to palletize and bundle various goods, yet provides strong and stable binding force. It securely secures cartons, wooden boxes, and other goods on pallets, preventing them from tilting or collapsing. It also avoids scratches and rust that metal clips can cause. This significantly improves warehouse stacking efficiency and cargo transportation safety, providing strong support for cost reduction and efficiency improvement in logistics and warehousing.