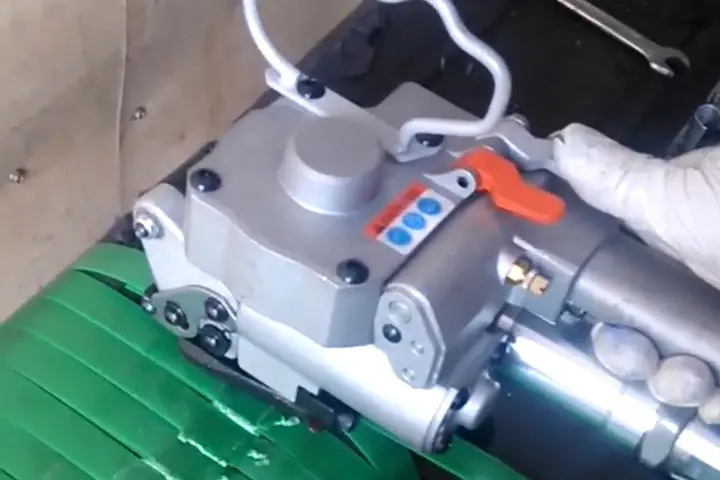

Electric PP/PET Strapping Machine DD190U

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

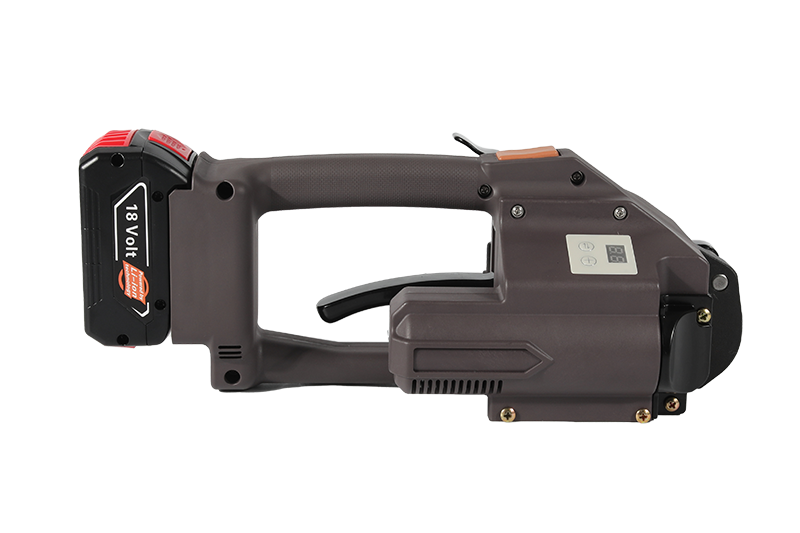

Product Overview

Battery Powered Strapping Machine 16-19mm

Battery Powered Strapping Machine for PP & PET Strapping Belt

Key Components

A typical electric strapping tool consists of several critical parts that enable its seamless operation:

Motor & Power Source: The core driver, usually powered by a rechargeable lithium-ion battery (for cordless models) or a direct AC power cord (for stationary/heavy-duty use). Cordless designs offer portability for on-site or large-facility use, while corded versions provide continuous power for high-volume tasks.

Strapping Feed Mechanism: A set of rollers or gears that guides the strapping material around the load, ensuring smooth, even feeding without jams.

Tensioning System: Adjusts the tightness of the strap around the load (tension levels are often customizable, from light for fragile goods to heavy for industrial bundles).

Sealing Unit: Creates a secure bond between two ends of the strap. For plastic straps, this is typically done via heat welding (melting the strap ends together for a strong, tamper-proof seal); for steel straps, it uses a buckle or crimp mechanism.

Cutting Blade: A sharp, durable blade (usually made of hardened steel) that trims excess strapping after sealing, eliminating the need for separate cutting tools.

Control Panel/Buttons: Intuitive interfaces (e.g., start, tension adjustment, emergency stop) that let operators easily configure and operate the tool.

Product Parameters

| Model | DD190U | |

| Applicable packing Strap | PP & PET | |

| Packing Strap Size | strap width | 16-19mm |

| strap thickness of PP | 0.6-1mm | |

| strap thickness of PET | 0.5-1mm | |

| Sealing way | friction heat sealing | |

| Tension force | 600N-4000N | |

| Tension speed | 13.5M/min | |

| Operation mode | button | |

| Battery power | battery | Li-lon 18V/4Ah |

| charging time | 60minutes | |

| no. of cycles per battery up to | 400-500 | |

| charger voltage | 100-240V / 50-60HZ | |

| long life | 2000 times | |

| Weight (w/ battery) | 3.9kgs | |

| Size: | 360*135*130mm | |

Common Applications

Electric strapping tools are widely used across industries where secure, efficient packaging is critical:

Logistics & Warehousing: Palletizing goods for shipping, securing carton bundles.

Manufacturing: Bundling pipes, rods, or finished products (e.g., furniture, electronics).

Agriculture: Securing bales of hay, grain sacks, or produce crates.

Construction: Strapping building materials (e.g., lumber, drywall) for on-site transport.

Courier & E-Commerce: Fast, reliable strapping of packages for last-mile delivery.