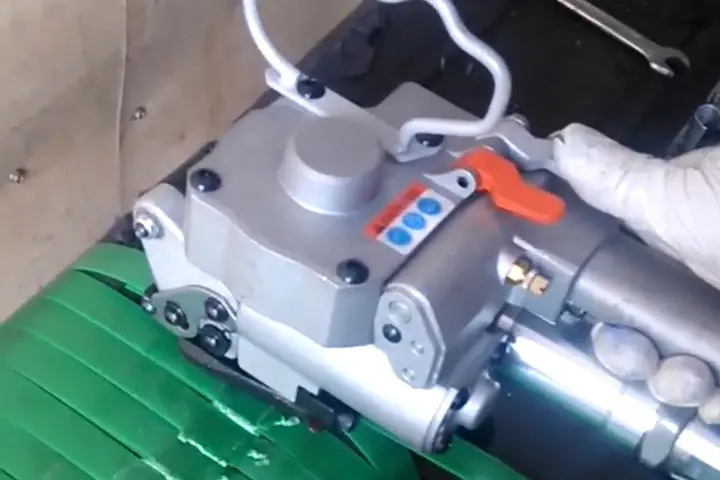

DYB32 Electric Steel Strap Sealer

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

igh speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Product Overview

The Electric Steel Strap Sealing Machine is a specially designed tool designed to securely secure and seal steel straps (or steel bands) around packages, bundles, or pallets for transport, storage, or industrial handling. This machine plays a vital role in the modern logistics and warehousing industries, improving work efficiency and ensuring the safety of goods during transportation.

This machine is typically equipped with an advanced electric drive system, enabling fast and stable tightening and sealing of the steel strap. The operator simply positions the steel strap in the designated position, and the machine automatically adjusts and closes the strap, reducing the complexity and labor intensity of manual operation. Furthermore, electric steel strap sealers offer a variety of functions, such as pressure regulation and sealing temperature control, to accommodate different package types and sizes.

In industrial applications, electric steel band sealers not only increase packaging speed but also ensure packaging quality, preventing loose or damaged goods during transportation. They are widely used in manufacturing, logistics centers, and storage facilities, particularly in environments that handle large volumes of goods, significantly improving work efficiency.

Key Features & Functions

- Automated Fastening

- Uses electric power to tighten and seal steel straps with minimal manual effort.

- Ensures consistent tension and secure clamping for load stability.

- Clasping Mechanism

- Steel Buckles/Clasps: Joins overlapping steel straps by crimping a metal buckle (or seal) around them.

- High-Pressure Crimping: Electrically driven jaws apply precise pressure to deform the buckle, creating a tamper-proof bond.

- Power Source

- Typically powered by battery (cordless)or electric mains (110V/220V)for portability or stationary use.

- Applications

- Widely used in logistics, warehousing, shipping, and heavy-industry sectors (e.g., securing pipes, lumber, construction materials).

- Advantages Over Manual Tools

- Faster operation, reduced labor fatigue, and higher repeatability.

- Suitable for high-volume strapping tasks.

Common Components

- Electric Motor: Powers the crimping mechanism.

- Crimping Head: Adjustable jaws to accommodate different strap widths (e.g., 10–32 mm).

- Tension Control: Ensures optimal strap tightness.

- Safety Lock: Prevents accidental activation.

Variants

- Handheld Electric Clasping Tools: Compact, portable units for fieldwork.

- Pneumatic/Electric Hybrid Models: For heavy-duty industrial use.