Product Overview

In industries like manufacturing, logistics, and construction, where efficient and stable strapping is crucial, a strapping device that combines powerful performance with flexible operation is often crucial for improving production efficiency. The DD160T/DD190T electric steel strapping tools, designed specifically for industrial applications, not only break free from the constraints of traditional wired and pneumatic tools but also redefine the standard for heavy-duty strapping operations with their dual advantages of "professional performance + ultimate ease of use."

1. Diverse adaptation to cover packaging needs in multiple scenarios

This battery-powered strapping machine boasts exceptional compatibility, precisely adapting to PP (polypropylene) and PET (polyethylene terephthalate) strapping, meeting the packaging needs of light to medium-weight goods. It's also specifically designed for heavy-duty industrial packaging, reliably strapping steel straps with widths ranging from 12-16mm and thicknesses of 0.5-1.0mm (the DD190T model is compatible with 19mm wide straps). Whether it's metal components in a manufacturing workshop, bulk cargo in a logistics warehouse, or stacking building materials on a construction site, it can easily handle these tasks, providing a unified and efficient solution for packaging operations across various industries.

2. Industrial-grade performance, combining power and long-lasting battery life

As industrial-grade tools, the DD160T/DD190T demonstrates exceptional performance. With an adjustable pulling force output of 600N to 4000N, the devices meet both the tight packaging demands of light goods and the high-strength bundling of heavy components, ensuring that the bundled goods resist loosening during transportation and storage. Furthermore, their optimized battery efficiency design allows the devices to complete approximately 350-450 strapping operations on a single full charge. Even during high-intensity continuous production shifts, frequent downtime for charging is unnecessary, significantly reducing operational interruptions and improving overall production efficiency.

3. Humanized design makes operation easier and safer

While pursuing high performance, the DD160T/DD190T also prioritizes the operator experience, lowering operational barriers and ensuring operational safety through detailed design.

Innovation in One-Handed Operation: The device weighs only 3.8 kg and features an ergonomic handle design, allowing operators to easily complete the entire process of "feeding, tightening, sealing, and cutting" with one hand, without the need for two-handed coordination or additional tools. This flexibility is particularly evident in confined spaces or packaging scenarios that require frequent movement, effectively reducing operator hand fatigue.

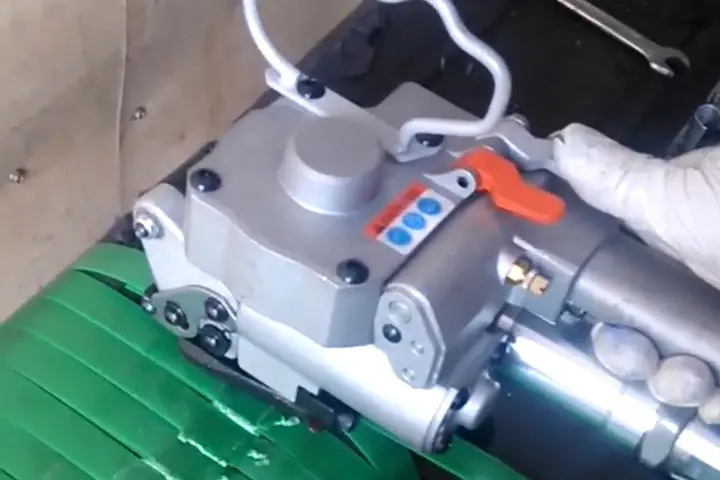

Reliable friction heat sealing technology: Using the industry's mature friction heat sealing process, it can achieve a secure seal with steel belts without relying on consumables such as steel belt buckles. The seal is strong and not easy to break, while reducing the procurement cost and replacement process of consumables. The heat sealing temperature and time are precisely controlled to avoid packaging failure caused by improper sealing, ensuring stable and reliable packaging every time.

Wireless freedom: Free from the constraints of wires of traditional wired tools, and without the need to connect to air compressors and air pipes like pneumatic tools, operators can move freely within the work area without being restricted by pipeline length and layout. This is especially suitable for packaging large cargo and dispersed locations, greatly improving operational flexibility.

4. Widely applicable, it becomes an efficient choice for industrial packaging

From end-of-line strapping in manufacturing, to warehouse and outbound bundling in logistics, to on-site securing of building materials in construction, the DD160T/DD190T, with its golden combination of "cordless freedom, one-handed operation, and professional sealing performance," perfectly adapts to the strapping needs of various industrial environments. Not only does it improve strapping efficiency and reduce labor costs, but it also reduces shipping losses through consistent strapping quality, saving businesses potential future losses. Whether you're a large-scale factory striving for efficient production or a small or medium-sized business emphasizing operational flexibility, this battery-powered strapping machine is an excellent choice for enhancing your strapping operations.

Product Parameters

| Model |

DD160T |

DD190T |

| Applicable packing Strap |

PP & PET |

| Packing Strap Size |

strap width |

12-16mm |

19mm |

| strap thickness of PP |

0.6-1mm |

0.6-1mm |

| strap thickness of PET |

0.5-1mm |

0.5-1mm |

| Sealing way |

friction heat sealing |

| Tension force |

600N-4000N |

| Tension speed |

13.5M/min |

| Operation mode |

button |

| Battery power |

battery |

Li-lon 14.4V/5Ah |

Li-lon 18V4/Ah |

| charging time |

60minutes |

| no. of cycles per battery up to |

350-450 |

| charger voltage |

100-240V / 50-60HZ |

| long life |

2000 times |

| Weight (w/o battery) |

3.8kgs |

| Size: |

360*135*130mm |

Product Features

Delivers 600N-4000N tension force

Provides reliable tightening for heavy-duty applications

Battery supports 350-450 straps per charge

Enables extended use with minimal charging breaks

Weighs only 3.8 kg

Maintains perfect balance of durability and portability

Utilizes friction heat sealing technology

Creates secure thermal fusion seals on steel strapping

Features intelligent controls

Ensures precise tension management and consistent performance

Combines superior power with operational efficiency

Ideal for demanding industrial environments

The use of DD160T/DD190T Electric Strapping Tool

The DD160T/DD190T is specifically engineered for 12-16 mm /19mm wide steel strapping with 0.5-1.0 mm thickness, making it ideal for securing heavy industrial loads and construction materials.

This tool excels in metal fabrication plants, lumber yards, and shipping warehouses where high-strength steel strapping is required for load stability and safety.

Its cordless operation makes it particularly valuable in large facilities and loading docks where mobility and freedom from power sources are essential for efficient operations.

The reliable thermal sealing system ensures secure containment of heavy goods, machinery components, and palletized materials during storage and transportation.