Battery Powered Strapping Tool DD160

Operate

convenient operation,smart and light, big power design

Sealing Method

weld friciton,with seal ,sealless,

beautiful and reliable connection joint

Performance

high automatic working performance, high controllability of tension and welding

Structure

high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages

Material

all the parts with High - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology

Patent

patent design and avoid fatigue

Product Overview

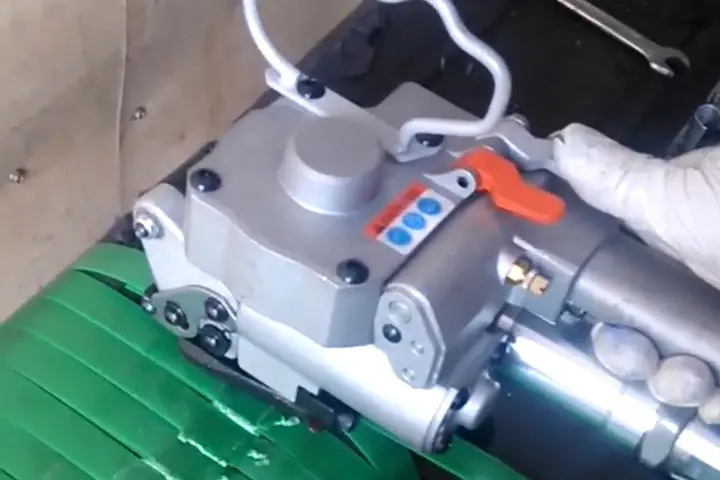

The DD160 is a battery-powered plastic steel strapping tool specifically designed for efficient logistics and industrial packaging. Its core function is to rapidly tension and seal PP (polypropylene) and PET (polyethylene terephthalate) plastic steel straps through friction fusion technology. It is suitable for strapping applications in industries such as electronic components, wood products, building materials, steel profiles, and paper products. Typical application scenarios include end-of-line product packaging (e.g., securing cartons and metal parts to prevent disarray), reinforcement of heavy pallets in logistics and warehousing (e.g., securing building material pallets and metal coils), and compressed waste baling at recycling stations (e.g., centralized handling of waste paper and plastic bottles). Its one-handed operation feature and lightweight 3.9kg body design provide significant advantages in confined spaces or mobile operations.

In terms of compatible plastic steel strap specifications, the DD160 supports PP straps with a width of 12–16mm (thickness 0.4–1.0mm) and PET straps with a width of 12–16mm (thickness 0.5–1.0mm). PET straps are often used for heavy-duty scenarios (e.g., steel bundling) due to their higher fusion strength, while PP straps are suitable for light to medium goods (e.g., electronic product boxes). Users can adjust the tension force (adjustable range 40–200kg) and fusion time via the onboard control panel, ensuring reliable sealing under tension forces exceeding 2000N for different strap materials. It supports both horizontal and vertical strapping modes, meeting multi-dimensional bundling requirements.

Product Parameters

| Model name | Battery Powered Strapping Machine DD160 | |

| description | widely used in paper industry,aluminum alloy, steel, wood, wooden box package, | |

| chemical fiber,cotton spinning,tobacco,chemical,metal products,etc.. | ||

| Feature | 1. convenient operation,smart and light, big electric power design | |

| 2. buckle free, friction fusion welding technology, beautiful and reliable connection joint | ||

| 3. high automatic working performance, high controllability of tension and welding | ||

| 4. no need to connect any power,easy remove | ||

| 5. excellent quality motor made by swiss. | ||

| 6.high speed tension,special structure design, easy to achieve tension and package of steel, aluminum ingots, heavy packages | ||

| 7.all the parts with high - strength aluminum alloy to keep long time use, reliable design and advanced manufacturing technology | ||

| 8.patent design and avoid fatigue | ||

| Applicable packing Strap | PP & PET | |

| Packing Strap Size | strap width | 13-16mm |

| strap thickness of PP | 0.6-1.2mm | |

| strap thickness of PET | 0.5-1.2mm | |

| Sealing way | friction heat sealing | |

| Tension force | 650N-3000N | |

| Tension speed | 13.5M/min | |

| Operation mode | button | |

| Battery power | battery | Li-lon battery 14.4V/5Ah |

| charging time | 60minutes | |

| no. of cycles per battery up to | 100-200 | |

| charger voltage | 100-240V / 50-60HZ | |

| long life | 2000 times | |

| Weight (w/ battery) | 3.9kgs | |

| Size | 130*140*370mm | |

Features of Battery Powered Strapping Machine DD160

Power Source & Battery: Utilizes a rechargeable 14.4V5Ah battery (often mentioned as a Bosch battery). The battery charges fully in approximately 30-60 minutes and can power between 100 to 200 straps per charge, depending on specific model conditions and settings

Strapping Compatibility: Designed for use with PP (Polypropylene) and PET (Polyester) straps. It typically handles strap widths of 12-16 mm and thicknesses ranging from 0.5-1.2 mm

Tensioning & Sealing: Features motorized tensioning and friction-fusion sealing in a single cycle. It can achieve a maximum tension force (tightening force) of 3000 Newtons (N) or 300 kg, ensuring secure bundles

Design & Portability: Notably lightweight, weighing approximately 3.9 kg (including the battery), with compact dimensions around 375mm (L) × 130mm (W) × 140mm (H). This makes it highly portable and suitable for use in various locations

User Interface & Functions: Includes a user-friendly interface with buttons and a display that shows battery charge level, tension force, and friction time. It often offers seven selectable settings for adjusting operation parameters. A strap count function keeps track of the number of straps applied

Performance: Capable of processing up to 80 bundles per hour

Advantages:

Cordless Convenience: Eliminates the need for external power sources or air compressors, offering greater mobility

One-Handed Operation: Enhances operator efficiency and ease of use

All-in-One Function: Combines tensioning and sealing in a single tool, streamlining the strapping process

Economic Efficiency: Using plastic straps (PET/PP) can be more economical than steel strapping for many applications, and it avoids the need for seals/clips.